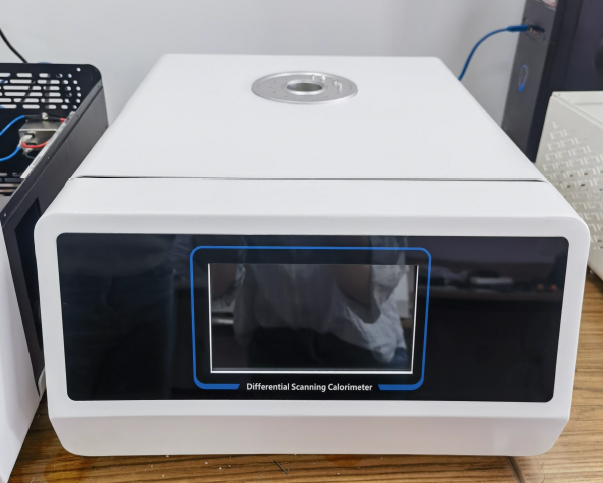

Differential Scanning Calorimetry

Differential scanning calorimetry (thermal flow DSC), as a classic thermal analysis method of thermal effects under controllable program temperature, is used in research and development, process optimization, quality control and failure analysis in various materials and chemical fields today. It has been widely used in various occasions. Using the DSC

method, we can study the phase transition of inorganic materials, the melting and crystallization processes of polymer materials, the polymorphism of drugs, the solid/liquid phase ratio of foods such as oils and fats, etc.

Usage:

Measure physical and chemical changes related to heat, such as glass transition temperature, melting point, melting temperature, crystallization and crystallization heat, phase transformation reaction heat, product thermal stability, solidification/cross-linking, oxidation induction period, etc.

Reference standard:

ISO 11357-2: 1999 Part 2: Determination of glass transition temperature;

ISO 11357-3: 1999 Part 3: Determination of melting and crystallization temperatures and enthalpy;

ISO 11357-3:1999 Part 6 Determination of oxidation induction period, oxidation induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT).

Price: Request Quotation

| DSC range | 0~±2000mW |

|---|---|

| Temperature range | Room temperature~600℃ |

| Timing frequency | 16.6Hz |

| Heating rate | 0.1~100℃/min |

| Temperature accuracy | 0.001℃ |

| Temperature resolution | 0.01℃ |

| Temperature fluctuations | ±0.01℃ |

| Temperature repeatability | ±0.01℃ |

| DSC noise | 0.001mW |

| DSC resolution | 0.01μW |

| DSC accuracy | 0.001mW |

| DSC sensitivity | 0.001mW |

| Experimental mode | FTC and STC can be set freely |

| Programmed temperature control | Full-stage 12-level temperature control with flexible settings |

| Temperature control method | Heating / constant temperature / cooling |

| Scan type | Heating / cooling / isothermal scanning |

| Atmosphere control | The two atmospheres can be set freely |

| Display method | 24bit color 7-inch LCD touch screen display |

| Data interface | Standard USB interface |

| Sampling rate | 1~10Hz programmable setting |

| Instrument calibration | Both the lower computer and the upper computer have multi-point temperature correction functions. |

| Parameter standards | Equipped with standard materials |

| Instrument size | 490*390*215mm |

Description

Contact Us:

Email : sales@qmnequipment.com

Contact : 1-647-724-2966

Machine Features

The integrated design of the whole machine reduces signal loss and interference, greatly improves signal sensitivity and resolution, and can obtain a more stable baseline.

Equipped with imported high-frequency core control processor, the calculation processing speed is faster and the control is more efficient. Use imported high-sensitivity sensors to effectively improve the sensitivity and accuracy of DSC signals. Independent atmosphere control can be intelligently set through software, and the instrument automatically switches the gas circuit system, making the experiment more efficient. The lower computer and upper computer of the equipment system have multi-point temperature correction functions to meet the needs of different experimental situations and improve the accuracy of temperature testing.

It has two experimental modes, FTC and STC. The temperature control is more friendly and flexible, and can meet the needs of different experiments in different application scenarios. The temperature control of the experimental process is more precise, and the analysis of sensor signals is more efficient. The full temperature control system adopts an optimized dynamic PID algorithm, which greatly avoids the shortcomings of the traditional PID algorithm and improves the robustness of dual-mode temperature control.

12-level programmable temperature control settings make experimental methods more diverse. The sampling frequency of the sensor signal can be set from 1 to 10Hz,

making the experimental method more flexible and the data more controllable. Dual temperature sensors that are independent of each other can test the furnace body temperature and sample temperature separately at the same time. The equipment system can conduct heating, cooling and isothermal related material experiments.

The instrument uses USB two-way communication, supports self-restoring connection, and has intelligent software design, with a baseline deduction function, automatic drawing of the experimental process, and intelligent processing of various data, such as calculation of heat enthalpy, glass transition temperature, and oxidation induction period. , melting point and crystallization of substances, etc.

WHY CHOOSE US

Quality Assurance: With QMN Equipment, you’re guaranteed to receive products that meet the highest standards of quality and reliability.

Competitive Pricing: Despite the advanced technology and superior quality, our products give you the best value for your investment.

Wide Range of Products: From hardness testers to universal testing machines and NDT/Ultrasonic technologies, our extensive portfolio ensures you have access to a diverse range of products.

Customization: We offer customized solutions tailored to your specific testing requirements, ensuring you get the most effective tools for your applications.