Metallographic Abrasive Cutter Manual with Recirculating Coolant System (Specimen Prepration) hardness

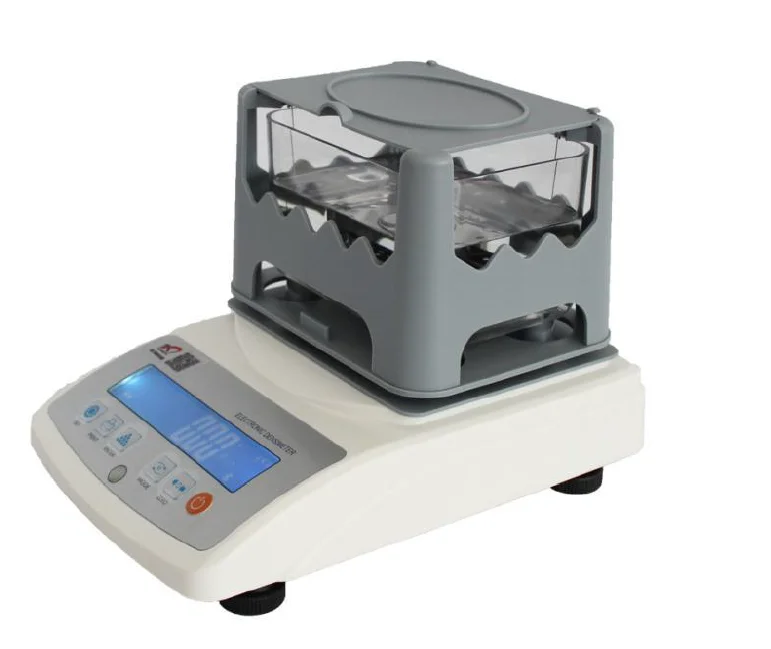

CT-250S/CT-250V is a desktop metallographic cutting machine designed and manufactured according to the principle of safety and environmental protection. It is

suitable for cutting samples of various metallic and non-metallic materials in order to observe the metallographic and petrographic structure of materials.

The machine has the advantages of stable operation, low noise, simple operation and safe use. It is one of the necessary equipment for making solid material samples in the laboratory.

Features:

– Push buttun cintrols for start and stop Emergency stop;

– Large viewing window with high brightness lighting system;

– Coolant automatically activates when cutter started;

– Clean-out gun for cleaning;

– Easy to operate, reliable, low noise;

– 24V isolated Electronics, Hood Lock and Electrical Brake

CT-250S/CT-250V is a manual cut-off machine, designed according to the principle of safety and environmental protection, equipped with safety lock and emergency stop button to ensure safety. The machine adopts WEG high-torque waterproof motor, ergonomic cutting handle, and simple control panel. Equipped with a 250mm/10" diameter cut-off blade, it is suitable for rapid cutting of various metal and non-metallic materials. It is one of the necessary equipment for sample preparation in the laboratories of factories, R&D Institute and college.

- Manually chop cutting,easy operation;

- Omron electronic switch accessories,safe and reliable;

- Extra large observation window with high brightness lighting system for easy observation of cutting process;

- Super cooling system ensures the workpiece won't burning while cutting;

- Equipped with independent water tank and filter, easy to collect the swarf and prolong the service life of the cutting machine;

- Rugged and reliable with low noise.

Product Feature

1.CT-250 desktop metallographic cutting machine has a novel and creative design, its performance can compare with the international similar product(Like Buehler)

2.Use Schneider motor, low voltage control, safe and reliable

3.Electronic brake technology, motor can be stopped immediately, safe enough.

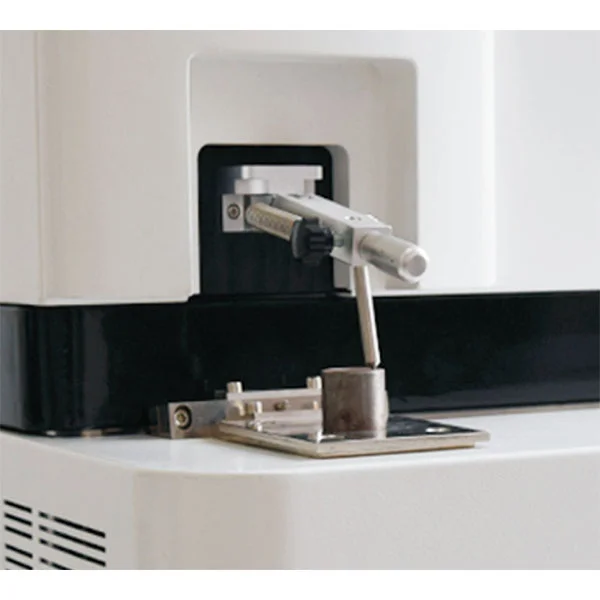

4.T-type worktable, double quick clamping fixture, which is beneficial to clamping all kinds of specimen.

5.Two different cutting modes: automatic and manual cutting, no burning swing cutting mode, 7 level cutting speed setting.

6.Oversized closed cutting operation room.

7.Simple and quick operation, high production efficiency

| Max. Dia |

Φ250mm |

|---|---|

| Cutting capacity |

Φ80mm |

| Feeding mode |

Manual |

| Dimension of table |

210x230mm |

| Power |

2.2KW |

| Wheel speed |

2800rpm |

| Weight |

100kg |

| Dimension WxDxH |

664x684x621(Close)664x898x829(Open) |