Precision High Temperature Test Oven

Chamber structure size:

1.Internal dimension: 500 (W) *600 (H) *500 (D) mm.

2. External dimension: 800 (W)* 1150 (H)* 7500 (D) mm is based on physical object.

3. Operating panel: The control panel is located above the platform.

4. Opening mode: single door opens from right to left.

5. The inner material is 430 mirror panel, 1.0mm thick.

6. External material: cold rolled steel plate,1.0mm thick, powder paint treatment.

7. Inter-layer: The inner box can be divided into two layers, and the distribution network board has two layers.

8. Thermal insulation material: high temperature resistant rock wool, good thermal insulation effect.

9. Sealing material for doorway is: high temperature resistant silicone strip.

10. Platform is equipped with brake-type movable casters, which can be moved and fixed.

Temperature control system:

1.The controller is 4.3 inch pure touch screen controller, which can calculate automatically, display PV/SV at the same time and set touch.

2. Timing function: Timing function in instrument.

3. Temperature sensitive line (PT100).

4. Signal output is 3-32V.

5. The heating controller is: SSR solid state relay has no contacts.

6. The heating material is: high temperature resistant heating tube.

7. Distribution uniformity of temperature deviation in the box (+2.0 ℃ ) (No-load test)

8. Supporting USB Historical Data Export.

Air supply system

1. Air circulation system: forced internal air supply cycle.

2. The motor is a high temperature resistant special type with a power of 370W/220V.

3. The wind wheel is a multi-wing turbine type of 7.5 inches.

4. There is one air inlet on the right side and one air outlet on the left side.

Power Supply Devices:

1. Voltage AC 220V/110V 50-60Hz Single Phase.

2. Power 3.5KW.

Safety Protection System

1. Over temperature protection system: When the temperature runs out of control and exceeds the set temperature of the over temperature protector, automatically stop heating and power supply, so as to protect the safety of your products and machines.

2. Circuit protection: grounding protection, fast insurance, circuit breaker, etc.

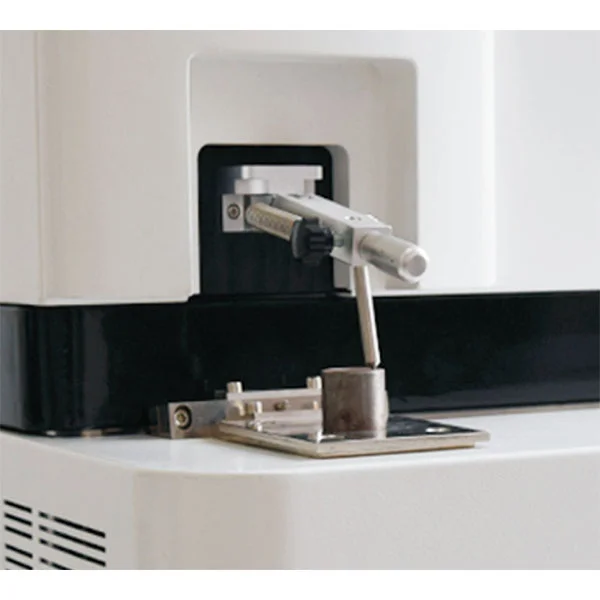

Model: DC0506N

Temperature range: -5 to 100℃

Temperature control precision: 0.1

The circular opening can be placed 200ml beaker, direct measurement of viscosity. The outer loop has the function of constant temperature cup can also be controlled constant temperature liquid lead to external, to meet different test requirements.

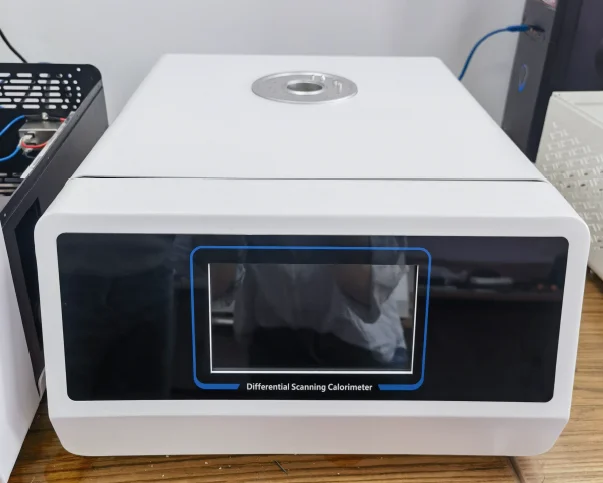

| Temperature range |

RT+10~350℃. |

|---|---|

| Heating rate |

100℃ for about 15 minutes. |

| Control accuracy |

(+0.5℃). |

| Display accuracy |

0.1℃. |