OES 8000 Optical Emission Spectrometer

OES 8000 Optical Emission Spectrometer

Based on the Multi-CCD detector and total spectrum technology, OES 8000 Optical Emission Spectrometer is able to detect all the spectral lines within the wavelength range. OES 8000 Optical Emission Spectrometer features a new design which eliminates the need of a vacuum pump and vacuum sealed chamber for accurate analysis. With extended wavelength range the instrument is suitable for the complex analysis of ferrous and non-ferrous metals.

Features

- High End Components- CARL ZEISS Grating and Optical Lens, Toshiba CCD Detector & Agilent Optical Fiber

- Polychromator operates without need of vacuum pump

- High Resolution: 10 pm/pixel

- Fast analysis: 35 seconds testing

- Excellent reliability and repeatability- 24/7 operation

- Compact Size

Application Fields

- Metallurgy, steel, ferrous & non-ferrous metals

- R&D, process control, inspection and sorting.

- Metal smelting, metal casting and processing industry

Price: Request Quotation

| After-sales Service | International Support |

|---|---|

| Application | Industrial |

| Warranty | > 1Year |

| Principle | Classic Spectrometer |

Description

Contact Us:

Email : sales@qmnequipment.com

Contact : 1-647-724-2966

Instrument Features:

Comprehensive analysis for the elements in most metals with the full spectrum detection based on the CCD detector with the full spectrum detection technology, the instrument can comprehensively detect the spectral lines of the most of the elements in the metal samples, and carry out analysis for multi-matrix and multi-elements easily. Therefore, it is convenient and inexpensive to install and add the matrix, channels and analytical program in customers' laboratory.

Professional test solution:

With long experience in analysis technology service,OES8000 Instrument provides users with the sound solutions for the analysis of ferrous and non-ferrous metal. The analysis programs in our solution are designed according to the classification of metal grade, meeting the various test demands of users perfectly. The analysis programs are factory-calibrated with international or national standard samples, and have been fitted and corrected by professional software. Just using a few pieces of the standardization samples supplied by QMN Equipment, the user can carry out the routine calibration easily. So it is unnecessary to purchase a large number of standard samples for the analysis program.

Top international suppliers provide the core components:

Dispersive device-The grating manufactured by CARI ZEISS in Germany ensure the excellent resolution.

Detector-CCD manufactured by TOSHIBA in Japan ensure the detection of spectrum sensitive and low noise.

Optical lens is manufactured by CARI ZEISS in Germany.

Optical fiber is manufactured by Agilent Technologies in America.

Excellent thermostat system for the polychromator

The thermostatic chamber is configured with a feedback heating device and the highly efficient thermal insulating layer, ensuring the temperature of the polychromator.

The thermostatic chamber suppress the drift of optical path due to the slight changes in the dimensions of the mechanical components in different temperatures. Meanwhile, the constant temperature is beneficial to the performance of photoelectric devices.

Applications fields:

OES8000 is widely used in the element analysis of ferrous and non-ferrous metal. The instrument can simultaneously analyze dozens of elements with a fast, accurate and stable performance, meeting the requirements in industrial development, process control, incoming inspection, product sorting, etc.

| Model NO. | OES8000 |

|---|---|

| Dispersive Element | Grating Spectrometer |

| Net Weight | 85kg |

| Wavelengths | Spark |

| Light Number | Monochromator |

| Packing Size | 45*75*80cm |

| Transport Package | Standard International Packing |

Reference

The following reference standards should be used when testing with OES8000:

- ISO 14284 Steel and Iron-Sampling and Preparation of Samples for the Determination of Chemical

Composition

- ASTM E 1806 Standard Practice for Sampling Steel and Iron for Determination of Chemical

Composition

- ASTM E 716 Standard Practices for Sampling and Sample Preparation of Aluminum and Aluminum Alloys for Determination of Chemical Composition by Spectrochemical Analysis

Preparation

- High hardness metal samples require grinding the surface. Typical samples include steel, Nickel,Cobalt alloy and others.

- Low hardness metal samples require turning the surface with the lathe. Typical samples include Aluminum, Copper, Zinc, Magnesium alloys and others.

Analysis

Place the sample on the spark stand and start the analysis with the software. The test is complete in less than 40 seconds and all the results of the customized elements are displayed. The results of the analysis can be stored in the software database or printed directly.

WHY CHOOSE US

Quality Assurance: With QMN Equipment, you’re guaranteed to receive products that meet the highest standards of quality and reliability.

Competitive Pricing: Despite the advanced technology and superior quality, our products give you the best value for your investment.

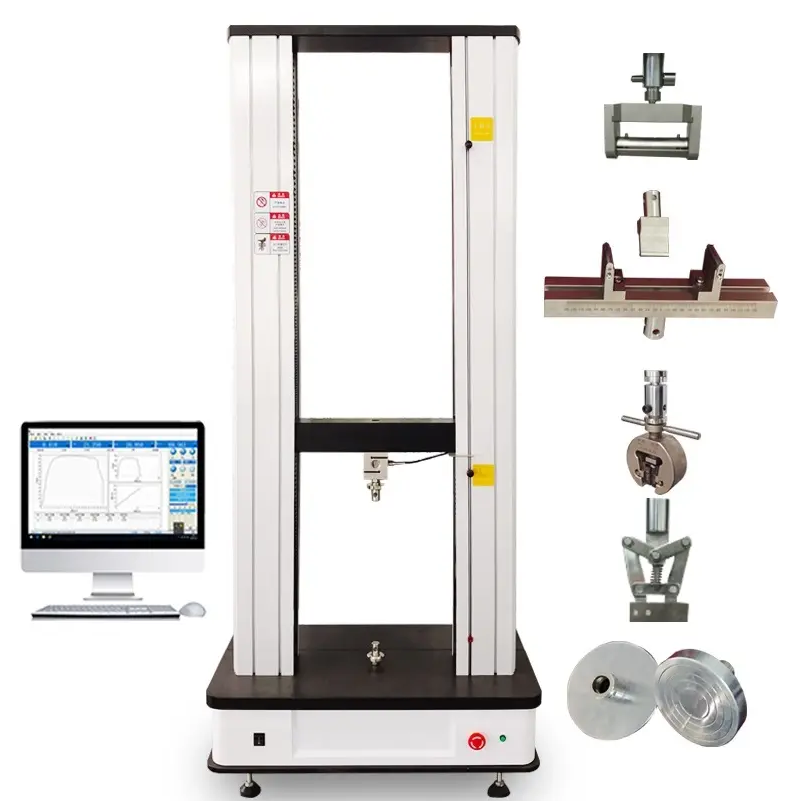

Wide Range of Products: From hardness testers to universal testing machines and NDT/Ultrasonic technologies, our extensive portfolio ensures you have access to a diverse range of products.

Customization: We offer customized solutions tailored to your specific testing requirements, ensuring you get the most effective tools for your applications.